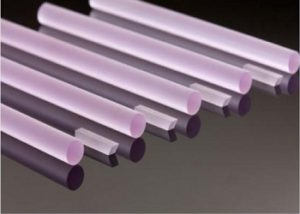

Nd:YAG Laser Crystal

Neodymium Doped Yttrium Aluminum Garnet (Nd:YAG) laser crystal is the most early and mature laser material adopted by R&D, medical, industrial and military customers. It is the ubiquitous presence for near-infrared solid-state lasers and their frequency-doubler, tripler, and higher order multiplier.

Advantages

1 ) High gain, Low threshold, High efficiency

2 ) Low loss at 1.06um, Good thermal conductivity and thermal shock characteristics

3 ) Mechanical strength, High optical quality

4 ) Material characteristics allow for various modes of operation (CW, pulsed, Q-switched, mode locked and cavity dumped.)

Specifications

Material | Nd:YAG |

Nd Dopant Level | 0.1- 2.5(+/-0.1)atm% |

Orientation | or |

Dimension | Diameter:1-50mm, Length:0.3-220mm(upon customer’s request) |

Diameter Tolerance | +0/-0.04mm |

Length Tolerance | +0.5/-0mm |

Wavefront Distortion | <λ/10 per [email protected] |

Chamfer | <0.1mm@45° |

Damage Threshold | >750MW/cm2@1064nm 10ns 10HZ |

Clear Aperture | >95% |

Flatness | λ/10 per [email protected] |

Scratch/Dig | 10-5 @MIL-0-13830A |

Barrel Finish | 50-80 micro-inch(RMS) |

Chips | <0.1mm |

Extinction Ratio | >30dB(depends on actual sizes ) |

Perpendicularity | <5 arc minutes |

Parallelism | <10 arc seconds |

Anti-Reflection Coating | R<0.15%@1064nm per surface |

High-Reflection Coating | Standard HR coating with R>99.8% @1064nm and R<5%@808nm |

Properties

Chemical Formula | Nd:Y3Al5O12 |

Crystal Structure | Cubic |

Lattice Constant | 12.01Å |

Melting Point | 1970° |

Rupture Stress | 1.3-2.6*103 kg/cm2 |

Density | 4.55g/cm3 |

Mohs Hardness | 8.5 |

Thermal Expansion Coefficient | [100] Orientation–8.2×10-6/oC (0-250oC) |

[110] Orientation–7.7×10-6/oC (0-250oC) | |

[111] Orientation–7.8×10-6/oC (0-250oC) | |

Laser Transition | 4F3/2 –> 4I11/2 |

Laser Wavelength | 1064nm |

Photon Energy | 1.86×10-19J |

Emission Linewidth | 4.5Å @1.064µm |

Stimulated Emission Cross Section | 2.7-8.8×10-19 cm2 @Nd 1at% |

Fluorescence Lifetime | 230µs |

Refractive Index | 1.8197 @1.064µm |