ZnSe Window

Zinc Selenide (ZnSe) Windows are ideal for a wide variety of infrared applications including thermal imaging, FLIR, and medical systems. This chemically vapor deposited material has wide usage in high power CO2 laser systems because of its low absorption coefficient and high resistance to thermal shock. Zinc Selenide (ZnSe) is a relatively soft material that scratches easily and it is not recommended in harsh environments because its Knoop Hardness is only 120. When handling, apply uniform pressure and wear Latex finger cots or gloves to prevent contamination.

Advantages

1 ) Low Dispersion

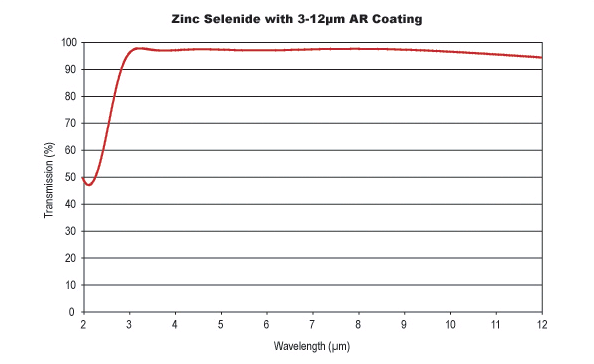

2 ) Available Uncoated or AR Coated

3 ) Ideal for Thermal Imaging, FLIR, and Medical Systems

Specifications

1 ) Diameter: 3~200mm

2 ) Diameter Tolerance: +/-0.2mm

3 ) Thickness Tolerance: +/-0.03mm

4 ) Aperture: >90%

5 ) Surface Quality: 60/40~10/5 (S/D)

6 ) Parallelism: <1 arc minute

7 ) Chamfer: 0.3-0.5mmx45°

8 ) Coating: AR/AR

Optical Properties

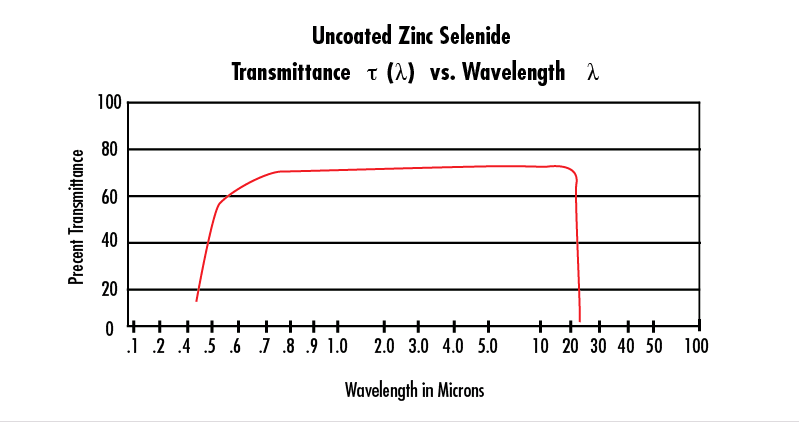

Transmission Range | 0.6 to 21 micron |

Refractive Index | 2.4028 at 10.6 micron |

Refractive Loss | 29.1% at 10.6 micron |

Crystal/Class Structure | Cubic, ZnS, F43m |

Thermal Properties

Thermal Expansion | 7.1×10-6 /℃ at 273K |

Thermal Conductivity | 18 W m-1K-1 at 298K |

Melting Point | 1525 ℃ |

Specific Heat Capacity | 339 J Kg-1K-1 |

Mechanical Properties

Density | 5.27 g/cc |

Hardness(Knoop) | 120 Knoop with 50g indenter |

Youngs Modulus | 67.2 GPa |

Bulk Modulus | 40 GPa |

Poisson Ratio | 0.28 |

Elastic Limit | 55.1 MPa(8000psi) |

Molecular Weight | 144.33 |

Chemical Properties

Solubility | 0.001g/100g water |

Technical Images