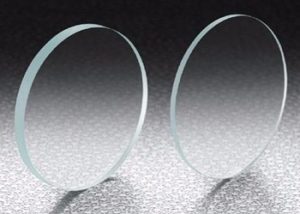

Sapphire Window

Sapphire Windows are manufactured from single crystal sapphire, making them ideal for demanding applications (such as laser systems) because of their extreme surface hardness, high thermal conductivity, high dielectric constant and resistance to common chemical acids and alkalis. Sapphire is the second hardest crystal next to diamonds and, because of their structural strength, sapphire windows can be made much thinner than other common dielectric windows with improved transmittance. Chemically, sapphire is single crystal aluminum oxide (Al2O3) and is useful in a transmission range from 0.2 – 5.5μm.

Advantages

1 ) Features Extreme Surface Hardness Chemical Resistance

2 ) Transmits Wavelengths Ranging From UV to Mid-Infrared

3 ) Thinner and Stronger than Standard Glass Windows

Specifications

1 ) Diameter: 3~250mm

2 ) Diameter Tolerance: +/-0.2mm

3 ) Thickness Tolerance: +/-0.03mm

4 ) Aperture: >90%

5 ) Surface Quality: 60/40~10/5 (S/D)

6 ) Parallelism: <1 arc minute

7 ) Chamfer: 0.3-0.5mmx45°

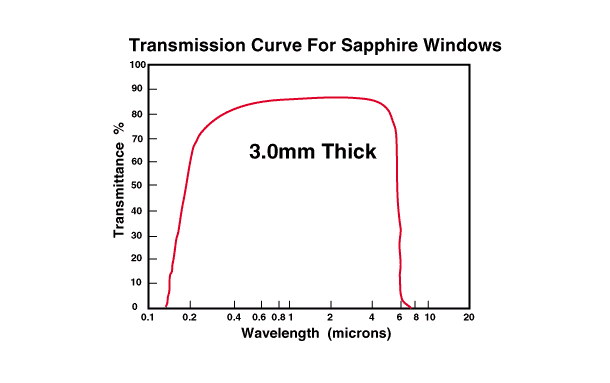

Optical Properties

Transmission Range | 0.17 to 5.5 micron |

Refractive Index | No 1.75449; Ne 1.74663 at 1.06 micron |

Refractive Loss | 14% at 1.06 micron |

Crystal/Class Structure | Trigonal (hex), R3c |

Cleavage Plane | (1011), (1012), imperfect |

Mechanical Properties

Density | 3.97 g/cc |

Hardness(Knoop) | 2000 with 2000g indenter |

Youngs Modulus | 335 GPa |

Shear Modulus | 148.1 GPa |

Bulk Modulus | 240 GPa |

Poisson Ratio | 0.25 |

Elastic Limit | 300Mpa (45.000psi) |

Technical Images